Monitoring & Targeting (M&T) is a structured approach to energy management. It enforces the principle that energy should be viewed as production cost, rather than an overhead.

The principles of M&T are a universal methodology and so not limited to energy utilities only. Therefore, the approach can be used for managing other production utilities and human resources what shall lead to decreasing of production costs.

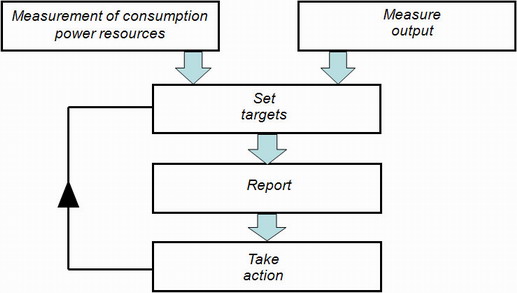

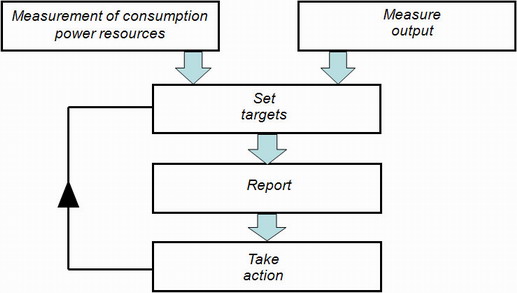

An operating M&T system consists of five major steps:

• Monitoring: Monitoring energy usage through a system of submeters to identifiable areas or individual pieces of plants, known as energy account centres (EACs).

• Targeting: Determining target levels for each of the EACs by relating the energy usage to a measure of activity, e.g. output of the production line in a factory or degree days for heating.

• Analysis and accountability: Establishing a regular, in most cases, weekly reporting system that gives a performance measure for each EAC and identifies variances in terms of financial gain or loss. A variance prompts an analysis, maybe including further investigation, and then an action.

• Energy Teams: Setting up energy teams that meet regularly to discuss ways of improving performance and carry out the actions identified. In addition, a regular feedback mechanism on performance to all levels of the company creates greater awareness and motivation to improve.

• Actions: Taking actions to reduce waste of energy. In an M&T programme, no and low cost measures and the main target. However, M&T gives leads, information and a feedback for high investment costs as well. Actions are essential for getting the savings!

The principle of M&T is illustrated on the figure above. As one can see the idea of M&T is rather simple, but it gives significant advantages if it is used right way.

M&T system is widely used in Western industrial companies, particularly in the United Kingdom. In 80-th years of the last century UK Energy Department has financed a demonstration project for implementation of M&T systems at 25 industrial companies of various types of industries. In 1994-96 the British consulting company March Consulting Group together with Enizan has fulfilled two years project for implementation of M&T systems at five Moscow companies. The project was partly financed by the British Know-How Fund in frameworks of technical assistance programme to Russia. Number of Case Studies was prepared based on the experience of implementation. You can learn about the experience of implementation of M&T at Moscow companies here (ññûëêà íà M&T_Case_Studies.pdf) (in Russian language).

Summarising the experience of using M&T at Western and Russian industries one could make the following conclusions about the advantages which gives use of M&T:

• better control of energy use, awareness of real value of energy, motivation to energy conservation;

• reliable information about cost of energy for each department and each process helps in making of commercial decisions, in planning and budgeting;

• reduction of energy cost by 10% in average, by 25% in some cases due to better control of energy use with zero capital expenditures;

• easier identification of energy efficiency measures and estimation of costs and potential savings from their implementation;

• more accurate estimation of energy savings and their values due to implementation of energy efficiency measures and projects.

Qualified specialists from Enizan are ready to share our experience and assist you in implementation of M&T system at your company.

109548, Ìîñêâà, óë. Øîññåéíàÿ, ä. 1, êîðï. 2

Òåë./Ôàêñ. (499) 176-85-30

E-mail: mail@enizan.ru